EXPERTISE

Traditional methods were applied for description of reservoirs and calculation of reserves in the early phase of the development of the NCS. In contrast to earlier field developments onshore and in shallow waters, the NCS environment proved much more challenging. Hence, risk had to be reduced by improved estimates of production profiles. This resulted in the development and application better methods and equipment for core analysis, which forms the fundamental principle behind RS Systems business.

X-Ray image of water displacing oil in a rock core sample (from A. Skauge et. Al)

The expensive field development operations on the NCS raise the need for improved data before making decisions for future field developments. This launched several research programs with the aim of improving laboratory techniques, laboratory equipment, reservoir – and geo-modelling software. Since the early seventies, there has been a lot of development to improve oil and gas production forecasts. For NCS, there have been many research projects to focus on improved descriptions.

Interpretation of data from displacement experiments in the laboratory is an example of how the quality of the results from the laboratory has been improved, and how this results in less uncertainties in developed reservoir model.

Traditional interpretation of a relative permeability experiment was based on many assumptions to use these results as in-put for production predictions. In modern petroleum laboratories, fewer assumptions must be made due to the quality of the equipment, and improved interpretation methodology.

EXAMPLES:

-

Traditional methods for measurement of rock propeties were done without any visualization of the displacement process itself. Hence, calculation of key data for this process had to be calculated based on assumptions using analytical methods. By the use of in-situ saturation measurements during the dispacement process we avoid these assumtions and determine the relative permeability curve (dsiplacement potential) by numerical simulation of the laboratory displacement process.

-

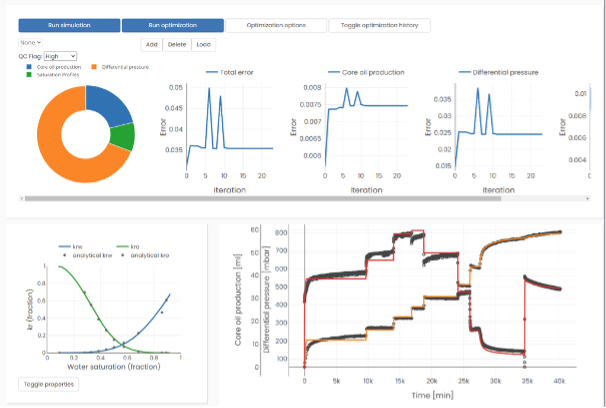

The illustration below shows a numerical simulation process using “SCALQC”. The simulator determines relative permeability and capillary pressure by history matching of measured displaced volumes, differential pressures and saturation profiles. Measured saturation profiles are not shown in this illustration.

LABORATORY DESIGN

Porosity, permeability, relative permeability, electrical conductivity, and capillary pressure are of the most important parameters measured or interpreted from laboratory testing.

Porosity and capillary pressure are important parameters for calculations of hydrocarbons in place (OIIP & GIIP). While permeability and relative permeability are important in-put for calculations of production profiles from an oil or gas field, and hence for the estimation of recovery from a potential reservoir.

These parameters are equally important for the description and planning of carbon storage projects.

As the petroleum industry and as carbon storage activity reach new geographical areas, there is an increased demand related to developing local capacities and competence. Development of local expertise and capacity has been a key element in many of RS Systems’ international projects.

-

Design of laboratory facilities

Listing of necessary laboratory equipment for the different development phases

Specification of displacement units and auxiliary equipment for EOR purposes

CONSULTANCY & TRAINING

RS Systems´ team has decades of experience in the following areas:

· experimental design

· design of laboratory test protocols and equipment

· reservoir condition testing

· data acquisition and data implementation in geo- and reservoir models

· interpretation and simulation of laboratory experiments

· Extensive training and testing of the equipment

Our experts are frequently involved in both consultancy and training activities in the above fields. Due to the complexity of the reservoir condition set-ups, many clients choose to involve RS Systems' specialists in the initial stages of the operation of delivered systems. This enables our clients to build their own experience in a controlled environment, as real reservoir studies are performed in the laboratory.

Training is a standard component in RS Systems’ deliveries of advanced equipment. Dedicated laboratory engineers, or technicians, will normally be involved in the commissioning and Site Acceptance Test (SAT) activities when the equipment is being installed at the clients’ facilities. Training in this phase include:

· Checking and testing of each vital component

· Testing of equipment modules

· Functional testing of complete equipment unit including SAT

CERTIFIED PRODUCTS AND SERVICES

RS Systems has established a portfolio of CE certified core holders, piston cylinders, accumulators and separators. This certification is according to the Pressure Equipment Directive (PED 2014 4/68/EU).

Based on clients’ request RS Systems can deliver complete set-ups with CE certification.

RS Systems is currently in a process for certification under the ISO-9001 standard, with the intent to be certified as a company in 2024